Project Description

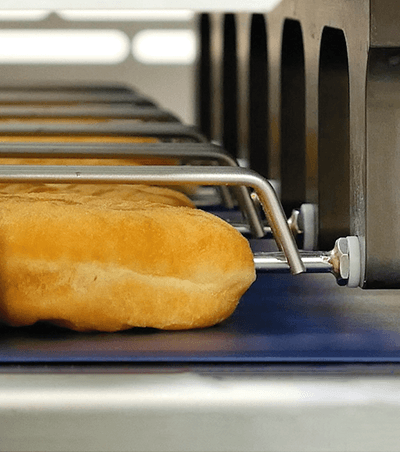

DONUT DECORATING SYSTEM

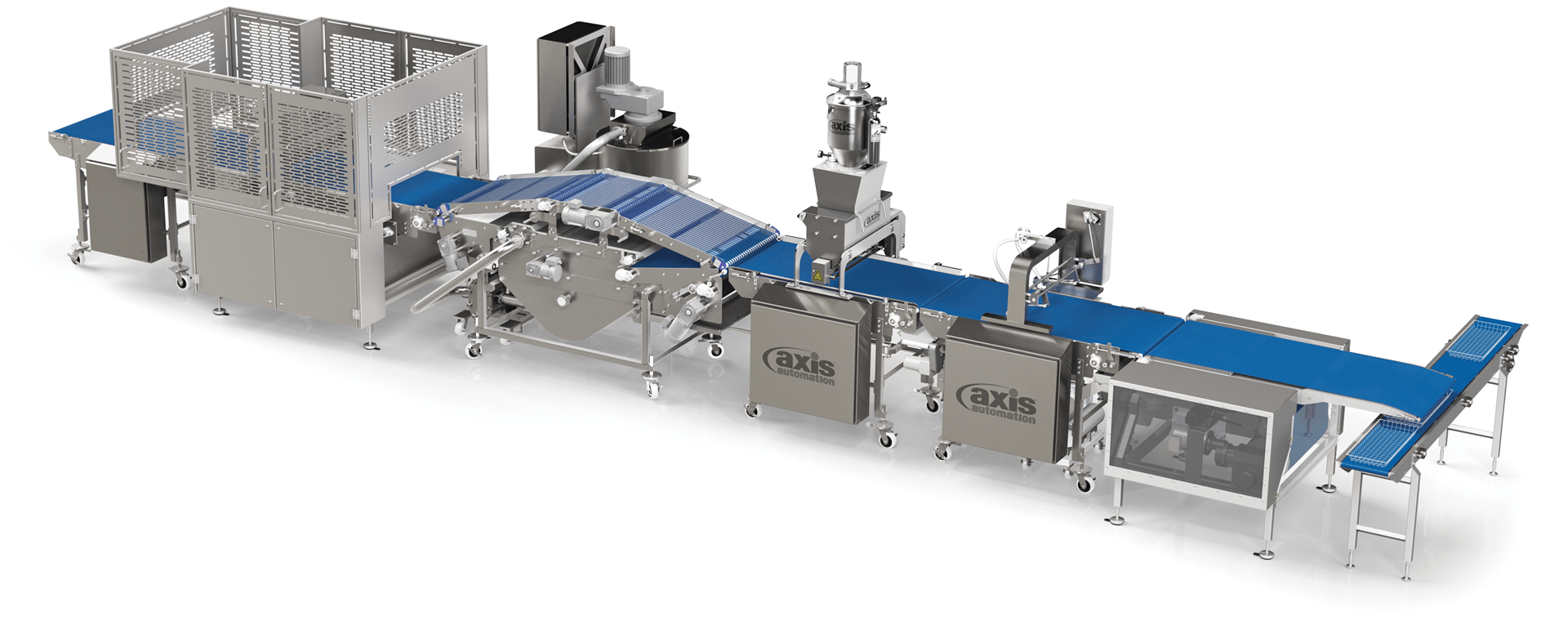

The AXIS Donut Decorating System is the most advanced decorating and finishing system on the market. Streamline your process, reduce cost and produce better-looking donuts at rates of up to 7,200 pieces/hr.

INJECTION

Fully automated injection from the top, side, or both. Volumetric accuracy of up to ±2% at rates of up to 30 cycles per minute. AXIS Injection systems handle all kinds of creams, jams, jellies, chocolates and more.

ICING & GLAZING

For uniform icing coverage and clean lines, the AXIS Half Icer and Glazer deliver like no other.

TOPPING

The AXIS Topper dispenses all types of dry, flowable ingredients. Reduce topping usage and waste with unrivaled accuracy and uniform coverage across the entire width of the deposit.

DRIZZLING

Dispense limitless drizzle patterns from zigzags and figure-8’s to cross-hatching and double loops. Create complex, custom designs or apply random patterns that mimic the look of decorating by hand.

INNOVATION at a glance:

- Standard system widths fit 4, 6, 8, 10 or 12 donuts across

- Automatic infeed and alignment systems to position donuts for injecting

- Modular design allows you to automate the parts of your line you need now and add additional features as you grow

- Produce donuts of all shapes and sizes including rings, shells, Long Johns, hearts and stars

- Fully automated refill and reclaim of fillings, icings and toppings

- Volumetric accuracies of up to ±2% for fillings and ±5% for toppings

- Precise temperature controls for uninterrupted flow of all icings and glazes

- Custom end-of-line solutions including paper feeding, robotic handling and basket loading