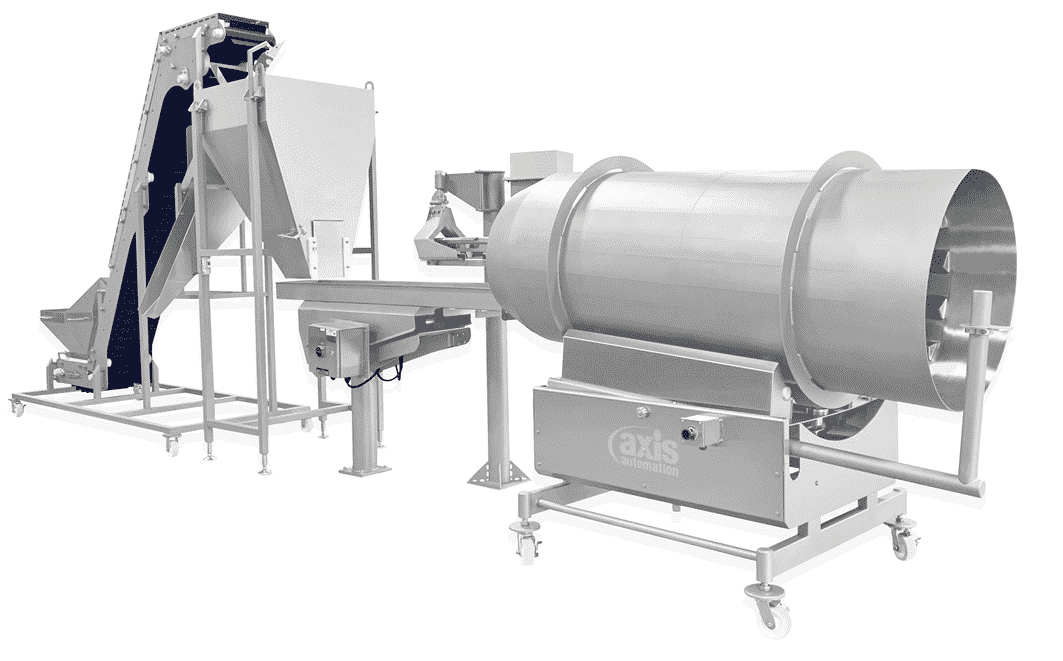

SEASONING SYSTEM

AXIS Seasoning Systems accurately apply liquid coatings and dry seasonings to all types of snacks and baked goods such as popcorn, chips and more. The gentle rotating action of the drum ensures that each piece gets evenly coated for consistent taste and visual appeal. Our systems are capable of single-stage applications of dry seasoning, two-stage applications

of liquid and dry ingredients or slurries for applications

that require heat and agitation.

USES:

CONVEYING

The AXIS Z-Conveyor gently and efficiently transfers product up

to an accumulation hopper for bulk storage in batch processes.

This proven conveyor design combines durability with sanitary

construction to dramatically reduce clean-up time compared to

modular belting. Designed for the demands of continuous

production, the Z-Conveyor is manufactured according to ANSI

Z50.2 standards using high-quality stainless steel construction and a food grade polyurethane belt.

METERING

Metering the flow of product to be seasoned or coated is essential to achieving proper coverage. In batch or continuous processes, an accumulation hopper mounted over a vibratory conveyor regulates the flow of product into a coating drum. The flow of product is controlled by adjusting the bed depth and speed of the conveyor.

SPRAYING

Precision spray bars and nozzles offer reliable metering of wet coatings. AXIS Spray Systems offer consistent performance with a variety of liquids including non-stick coatings, butter, oil, freeze barrier coatings, chocolates and glazes. Designed for flexibility, standard spraying systems come in a variety of configurations including Pulse Width Modulation (PWM) for high-frequency pulsing, clog-free nozzles, air atomized or hydraulic nozzles, heated tanks and product agitation to keep inclusions in suspension.

SEASONING

Metering and distribution of dry ingredients is essential for even, uniform coverage. The variable speed auger feeder precisely meters seasonings onto a vibratory scarf plate, while the vibratory scarf feeder distributes an even curtain of product inside the coating drum. For the ultimate in accuracy, the AXIS Seasoning System can be configured with a loss-in-weight system to regulate the ratio of seasoning to product entering the coating drum.

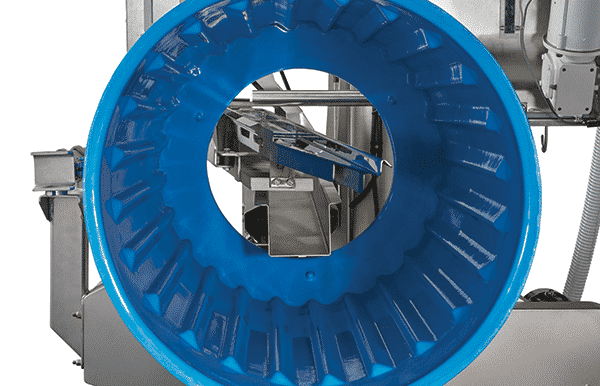

COATING

Selecting the right style of drum is critical for optimal coverage and visual appeal. AXIS Coating Drums come in a variety of styles and sizes to ensure uniform coating, gentle handling and minimal breakage. Select from stainless steel or FDA-approved polypropylene; fixed or removable liners, seamless or perforated drums, helical or bi-directional flights.