PIE & QUICHE LINE

The AXIS Pie Line 750 is a fully automated pie production line capable of accurate and efficient dough depositing, pressing, filling and lidding. The system is compatible with pies, quiches, and tarts ranging in size from 3”-12” in diameter. Reach your optimal throughput with rates of up to 30 cycles per minute. Standard designs allow for configurations of 2, 4 or 6 pies across, yielding up to 10,000 pies per hour (6-up configuration).

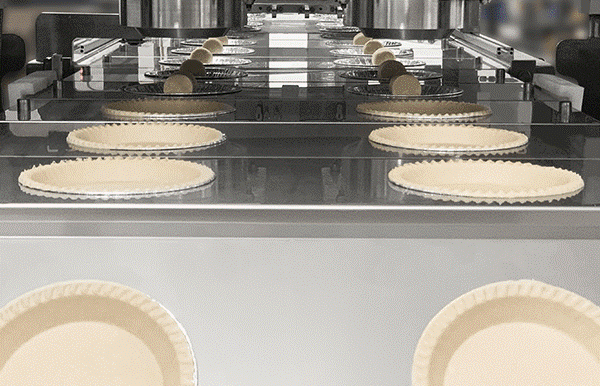

DENESTING

The AXIS Tray Denester automatically denests pie tins and places them into an indexing conveyor that transports them to the AXIS LD Depositor. A vacuum style denester below the conveyor ensures perfect placement of tins at every index. Sensors ensure all trays are denested before advancing to the next station.

BILLET FORMING

The AXIS LD Depositor is the most flexible solution in the industry for billet forming and depositing. The innovative design allows you to adjust depositing volumes and maintain overall volumetric variation of less than 2%. Servo-driven, stainless-steel pressure rollers ensure precise portioning without compromising the quality of your dough. The perfect synchronization of the pressure rollers and metering rollers provides ultimate accuracy. Interchangeable lobed depositing heads and masking plates allow for easy changeover to other sizes and configurations.

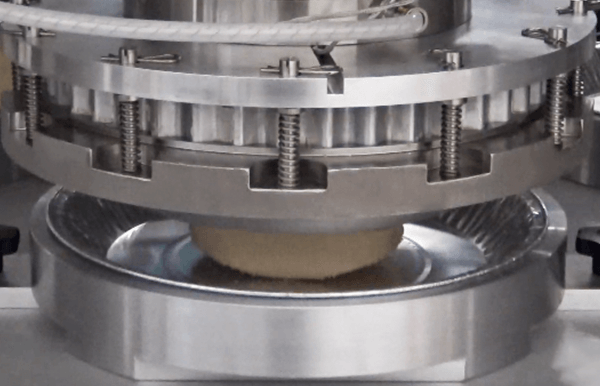

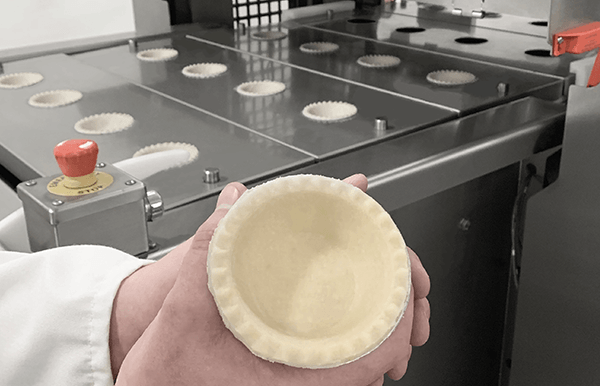

PRESSING

Smooth or ridged, vertical or angled walls, the AXIS Press forms pie molds for all types of crusts. The temperature-controlled heads operate between 0-200°F for blocking and stamping without sticking. Air-manifold valves built into the dies make the removal of moist or sticky dough clean and efficient — no need for flour dusting or greasing. Servo controls and hydraulic options are fully programmable for precise control over downward pressure and speed. Produce even crust thickness and uniform dimensions without generating scrap or reclaim.

INNOVATION at a glance:

- Custom tooling options allow for variation in thickness of base, side walls and crimp pattern

- Switching from sheeted to extruded doughs allows for maximum flexibility in controlling wall thickness and crust patterns

- Modular design allows you to automate the parts of your line you need now and add additional features as you grow

- Designed for midsize and large wholesale bakeries with ease of sanitation, maintenance and high performance in mind

- Add optional AXIS PD Depositors to handle all your fillings — liquid, semi-liquid, medium to high viscosity, with or without inclusions

- Optional topping stations allow you to apply a range of dry toppings and most ingredients like streusel anywhere in your process

- Add lidding of molded lattices and lids for that finishing touch

- Automatic end-of-line solutions for downstream processing can be fully customize and integrated to fit your application