PRECISION: Injecting profit into your process.

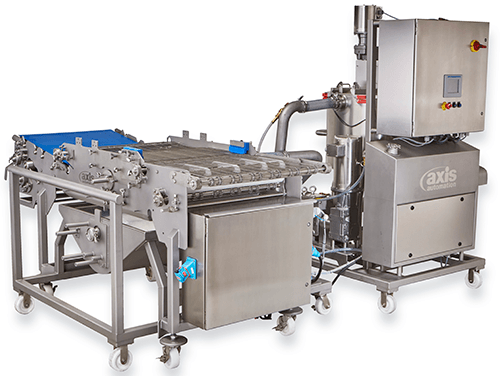

For perfectly filled donuts, cakes, muffins, bread and pastries, upgrade to fully-automated injecting equipment. Boost accuracy and productivity with the high-speed, precision filling of an AXIS injection system. Engineered with precision in mind. Servo-controlled ball screws and high tolerance machining ensure accuracy, control and replicable results. Maintain consistencies of ±1% by volume at rates of up to 30 cycles per minute. Our unique “suck-back” vacuum feature prevents leakage during retraction. Custom filling profiles and needle configurations produce results that other injection equipment cannot.

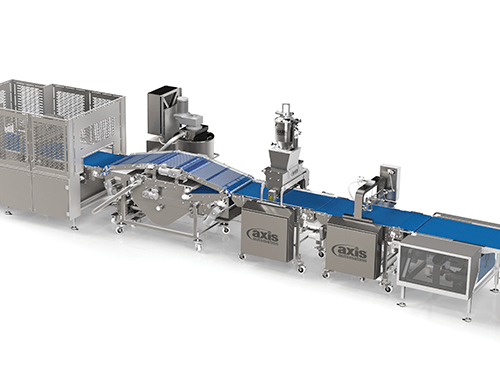

FLEXIBILITY: Top or side? It makes no difference.

AXIS injection systems are flexible enough to do in-line, top or side injection with the same equipment. Whether your product is long and narrow, short and round, heart-shaped or completely unique, our injection systems can easily accommodate any shape or size. Fillings can be hot or cold, with or without inclusions. From donut injection to cupcake filling, this bakery filling equipment can handle a wide variety of crèmes, jams, jellies, custards, syrups, icings, and chocolates with ease. Incorporate an AXIS injection system into your existing line, or let us custom design a solution for your application.

INNOVATION at a glance:

- Easily remove injection head for quick product changeover or sanitation

- Servo controls instead of pneumatics to maintain accuracy over time

- Suitable for fillings such as crèmes, jam, syrup, whipped cream, icing and chocolate

- Dedicated volumetric piston for each injection needle to ensure accuracy

- Available with vertical and horizontal moving head

- Jacketed hoppers for temperature control of fillings

- Needle designs to prevent buildup and clogging

- Well suited for large volume deposits or for filling multiple rows per cycle

- Automatic Clean in Place (CIP) system available for quick and easy sanitation

- Design ensures consistency across all depositing lanes

- Standard or custom needles and nozzles to handle any injection profile

- “Suck-back” feature prevents product leakage from injection point