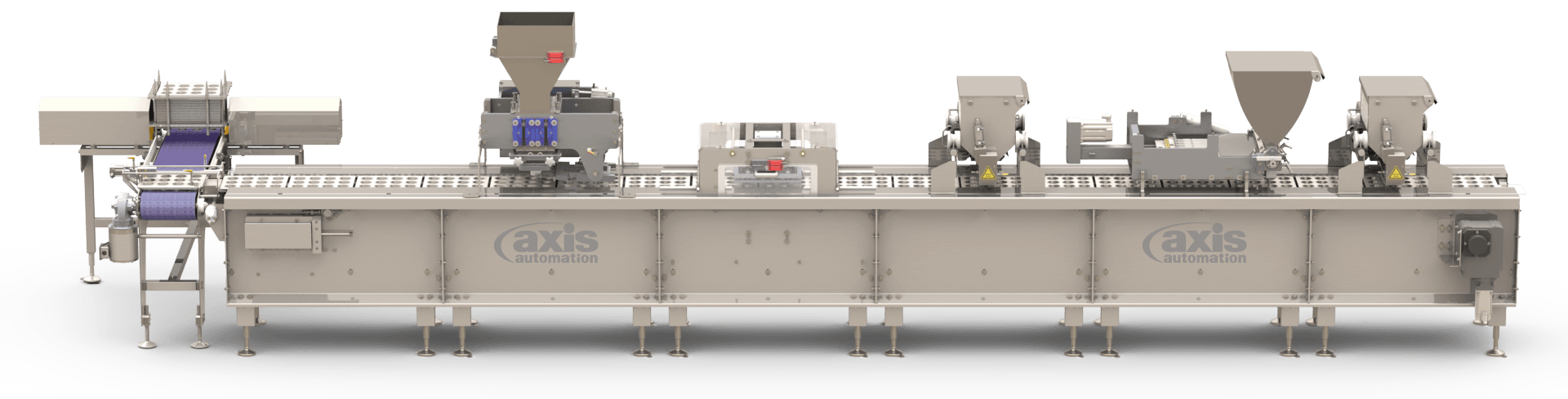

MINI TART LINE

The AXIS Mini Tart 500 produces tarts of every shape and size at rates of up to 60 cycles per minute. Get the precise control and efficiency of a fully automated line without sacrificing authentic quality.

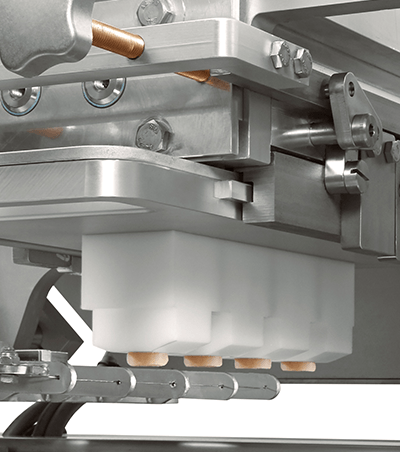

DEPOSITING

Deposit all types of dough, medium to high viscosity, with or without inclusions. AXIS LD Depositors produce consistently high quality with gentle, damage-free handling at rates of up to 120 cycles per minute.

FILLING

AXIS PD Depositors dispense any filling, thick or thin, with or without inclusions. Jacketed hoppers maintain precise temperature control to preserve the integrity of your product and maintain flow.

TOPPING

Cinnamon, pecans, coconut, streusel – AXIS Topping solutions dispense any dry or semi-moist toppings for a perfect, finished look. For multiple toppings, add a second topping station to your line or try the AXIS Spot Topper for precise placement.

INNOVATION at a glance:

- Modular design allows you to incorporate the parts of your line you need now and add additional equipment as you grow

- Automatic tray denesting and end-of-line unloading

- Fully automated refill and reclaim options available

- Capable of pre-fill and post-fill topping

- Servo-driven metering rollers and lobed pumps for as little as ±2% volume variation

- Even thickness and uniform dimensions without leaving scrap dough

- Dense, difficult fillings are handled gently and efficiently with ease

- Reduce topping usage and waste with unrivaled accuracy and coverage