Project Description

PRECISION: Glazing perfection.

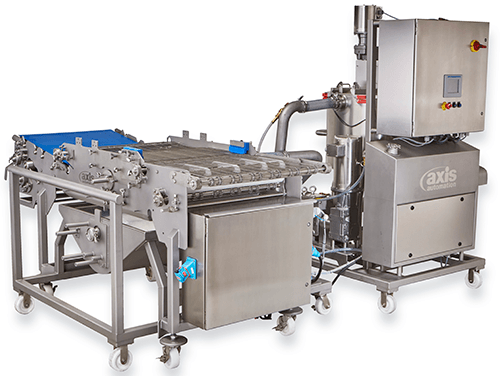

The AXIS Glazer deposits a continuous, uninterrupted flow of glaze, without the mess.

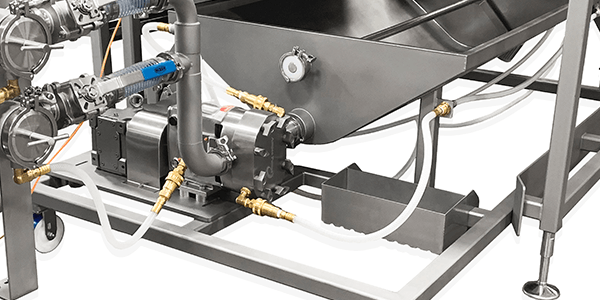

Our unique recirculation system returns glaze to the heating kettle to maintain optimal temperatures and minimize glaze transfer to downstream equipment. The glazing depositor features water jacketed tanks, pipes, pumps and reclaim hoppers to minimize build-up while screening and filtration eliminate downtime.

FLEXIBILITY: Built for productivity.

Whether your glaze is heated or at room temperature, thick or thin, our donut glazers deliver consistently uniform and perfectly-glazed donuts every time. For quick-change of depositing widths, you can narrow the stream while production is running. Integrate our glazing bakery equipment with plant steam or supply with on-board heaters and pumps. Designed for quick and easy sanitation.

INNOVATION at a glance:

- Deals with a high BRIX glazing solution

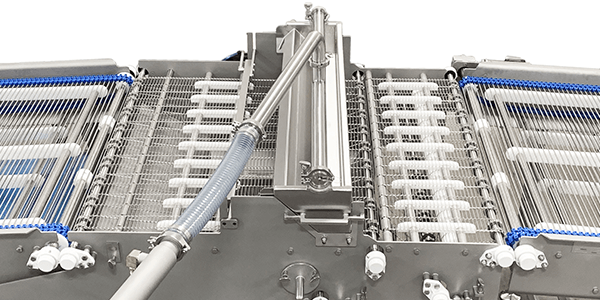

- Water jacketed waterfall station

- Glazing recirculates to heated holding tank

- Run glaze-free through freezers

- Adjustable conveyor nose bars positioned with gaps to minimize glaze transfer

- Open conveyor belt design minimizes glaze build-up

- Piping uses sanitary quick disconnect couplings

- Reclaim system mounted on cart for easy removal and sanitation

- Variable speed blower and manifold strip excess glaze from products

- Adjustable flow rates use PD pumps for maximum precision and repeatability

- Belt scraper has quick release feature for cleaning and sanitizing