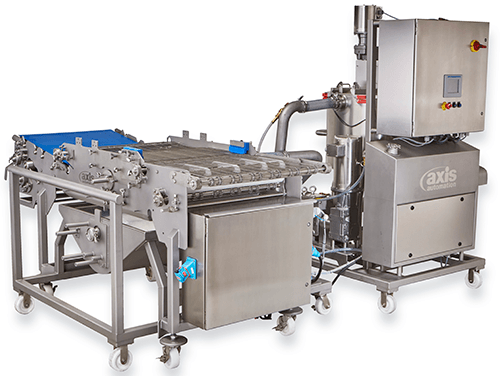

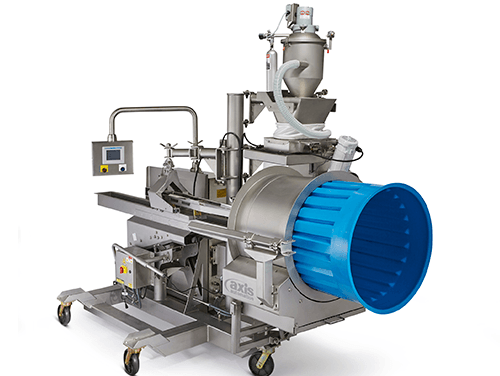

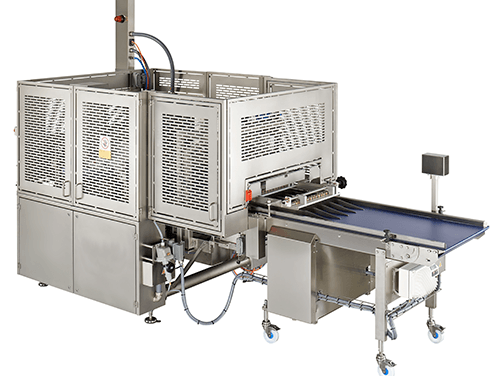

The AXIS Mini Filler is a single operator injection system capable of filling all types of traditional and bite-sized products. Inject from the top, side or both at rates 3-5x faster than manual systems.

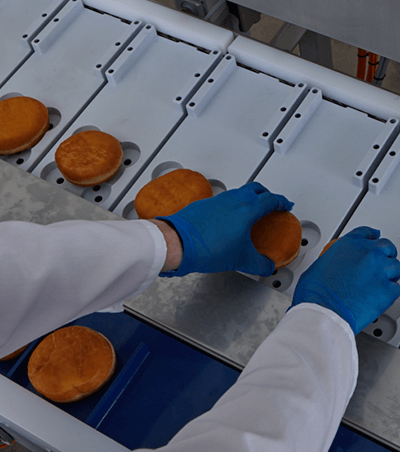

AUTOMATED INJECTION STATION

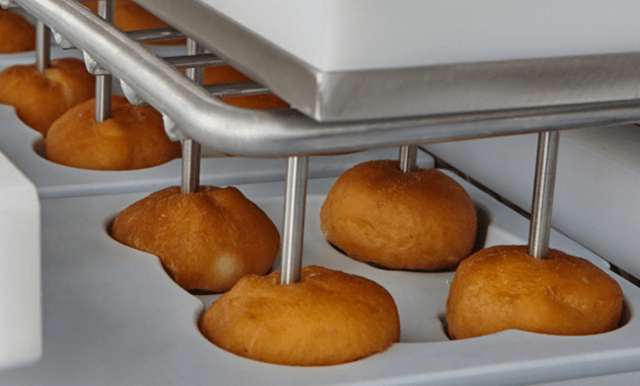

Donuts pass from the indexing conveyor to the automated injection station. For top injection, donuts are positioned under a stationary stripper plate to hold the donuts in place. The injection assembly advances vertically down onto the donuts and filling is injected as the needles are withdrawn. For side injection, donuts are positioned in front of the needles. The injection assembly advances onto needles with a pneumatically operated pusher. Filling is injected as the needles are withdrawn leaving perfectly filled donuts and no mess.

INNOVATION at a glance:

- Fills all types of bite-sized products including bagel bites, mini muffins and donut holes

- Inject donut holes, shells and rings from the top, side or both

- Micro-precision volumetric piston adjustment

- Individual cylinder adjustment of up to 5cc for volumetric accuracy of up to ±2%

- Quick change over of injection needles

- Pistons can be disabled for rows that will not be injected

- Servo-controlled screw feeder for precision filling

- Use as a stand-alone system or integrate into your existing production line with an upgraded injection head

- Optional automated outfeed system can be used to feed donuts into half icing, tumbling drums, or topping