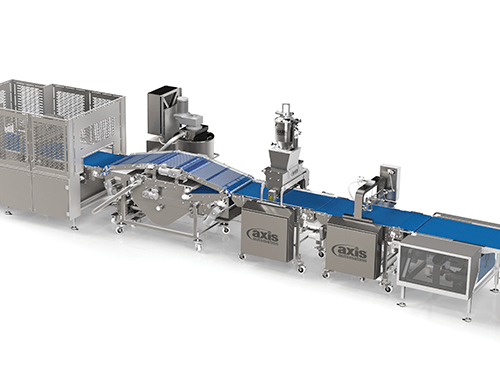

Project Description

PRECISION: The one and only tail-free half icer.

The AXIS Half Icer (US Patent No. 10,477,868) applies a smooth, polished layer of icing without mess or waste for better-looking product and greater profit. Low shear pumps, custom proportional valving and proprietary designs ensure uniform, consistent coverage and prevent degradation of RTU icings even after hours of use. Water-jacketed elements and insulated kettle regulate product temperature to stay within ±1°F. The unique “no-tail” decorating feature delivers sharp clean icing lines.

FLEXIBILITY: Fastest results in the industry.

AXIS icing bakery equipment handles a wide variety of icing viscosities with ease. Whether you’re working with water-based or fat-based ingredients, look forward to the fastest production rates in the industry. Connect the AXIS Half Icer to an onboard by-pass conveyor or link to other icers in series for quick color-changes that won’t interrupt production. Use as a donut icer for rings, shells and Long Johns or apply to your cookies, pastries and breakfast bars. With its flexibility, small footprint, easy-clean capabilities and great-looking results there really isn’t a better decorating solution.

INNOVATION at a glance:

- Kettle design prevents icing build-up with independent agitators and sidewall scrapers

- Minimizes shear of icing

- Water jacketed stainless steel Positive Displacement (PD) Pumps

- Adjustable bath height for greater control over coverage

- Triple walled kettle for external insulation layer with internal jacketed hopper

- Internal heating elements or external steam supply

- Automatically alerts if icing exceeds normal operating parameters

- Bypass conveyor to divert donuts from icing bath in continuous operation

- Water jacketed piping ensures continuous flow of material, even at startup

- Water jacketed reclaim hopper keeps product at ideal temperature

USES:

- Donuts

- Cookies

- Breakfast bars

- Shells

- Rings

- Long Johns

- Hearts

- Stars

- Donut holes

- And more