PRECISION: Hit the bullseye every time.

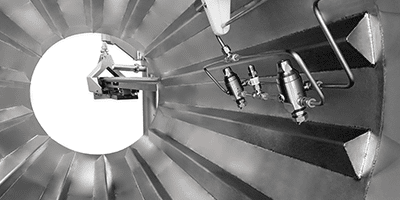

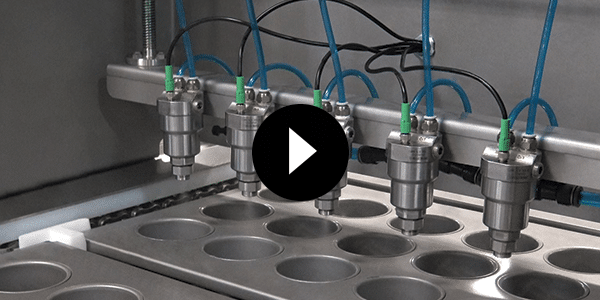

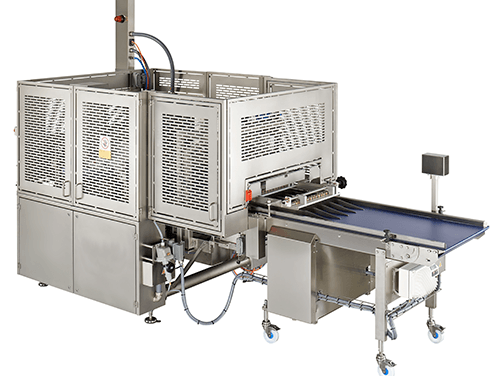

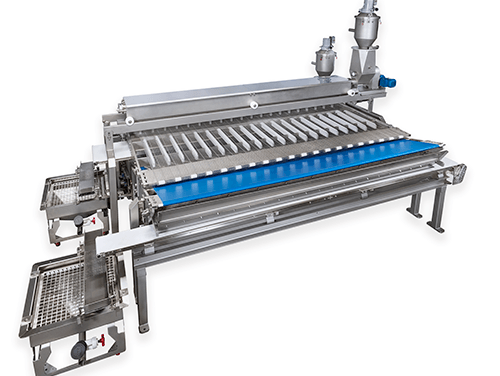

Lightly spray dough before seeding, grease baking pans, or mist cakes with water before seasoning. It’s all about precision, and AXIS Spraying Systems are designed to deliver. Bakeries require precise control over liquid flow to ensure that costly coatings are conserved. For complete coverage and minimal waste, our oil spraying equipment features overspray recovery and mist elimination to consistently apply proper volumes of liquid. Apply product only where it’s needed, when it’s needed, at controlled application rates. Dispense consistent, reliable, and repeatable patterns.

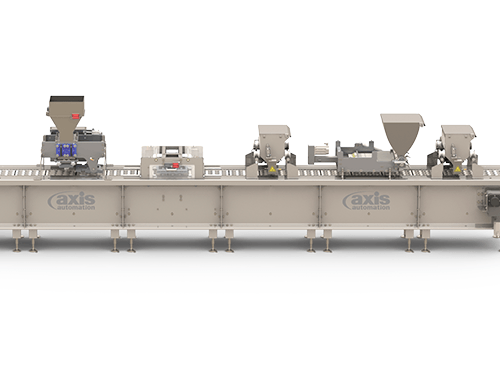

FLEXIBILITY: We’ve got you covered.

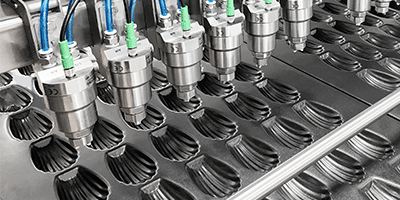

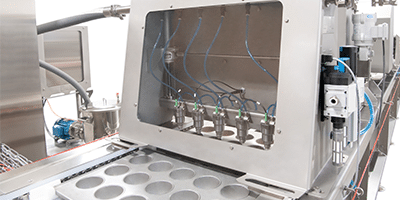

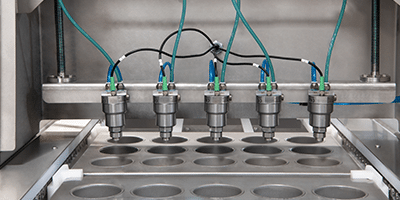

Designed for flexible application, AXIS spray coating systems come in a variety of nozzle and pump styles for custom spraying profiles. Accurately target baking pan cavities or set a wide spray angle for sheeted product. Apply non-stick coatings, butter, oil, freeze barrier coatings, chocolates and glazes with ease. Use air atomized or hydraulic nozzles. Apply food coatings continuously or try high-frequency pulsing nozzles for intermittent applications. When combined with our robust, sanitary conveyor designs, the AXIS Spray System is a complete, turnkey solution.

INNOVATION at a glance:

- Precision spraying minimizes spread of atomized solution

- Controlled deposit volumes within ±3% for reduced waste

- Fully adjustable flow rates, fluid pressure, deposit volume, nozzle configuration, and spraying interval

- High frequency, pulsating nozzles for intermittent applications

- Top-only, bottom-only, or top-and-bottom spraying

- Gentle handling of viscous and non-viscous coatings

- Automatic on/off control for each nozzle

- Overspray recovery and mist elimination

- Portable supply cart with holding tank to replenish product without disrupting operation

- Reclaim system is tolerant of salt, crumbs, and debris in liquid

- Production rates are easy to adjust and remain consistent over time

- Easy maintenance, cleaning, and operation