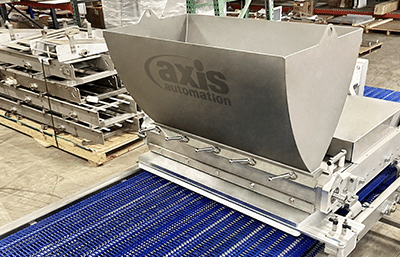

PD DEPOSITOR

Included: rubber-belted conveyor, controls, hopper, pistons, d-valve and tooling

The AXIS PD Depositor is a servo-driven volumetric piston depositor that can be used to accurately inject or deposit all types of batters, cream fillings, icings, jams, chocolates, and other flowable, non-compressible materials.

For more information or to get pricing, contact us now.

FEATURES:

- Servo-controlled dosing pistons to advance fillings through the nozzles

- Pneumatically operated two-way rotary valve directs product flow from the hopper to the dosing pistons

- All stainless-steel construction and food grade materials

- Interchangeable nozzle manifold allows you to change nozzle styles and spacing

- Stand-alone depositing head support frame with height adjustable legs

- Precise shut-off valves and unique suck-back feature for clean deposits and less waste

- Individual adjustment of cylinders up to 5% by volume (tools required)

SPECIFICATIONS:

- Deposit width: 700mm (27.5”)

- Hopper capacity: 60 gallons

- All components in the product zone are in stainless steel AISI 304 or food grade materials

- Main frame and outside plating in stainless steel AISI 304, zinc coated steel or anodized aluminum

- Chains and gears in chromium-plated steel

- Bearings are waterproof

- Electric enclosures attached to the equipment are Nema4X stainless steel

- Electric enclosures/cabinets separate from the machine in stainless steel

- Electric push buttons on the machine are high-impact plastic

- Compressed air supplied at 80 PSI (5.5 bar) to standards DIN ISO 8573-1 class 3 (air compressor not included)

- Standard environmental conditions for the equipment:

- Ambient temperature from + 15° C. to + 25° C (from +59° F to +75° F)

- Relative humidity from 10% to 80% in environment free from condensation

- Maximum variation of the supply voltage: ± 5%